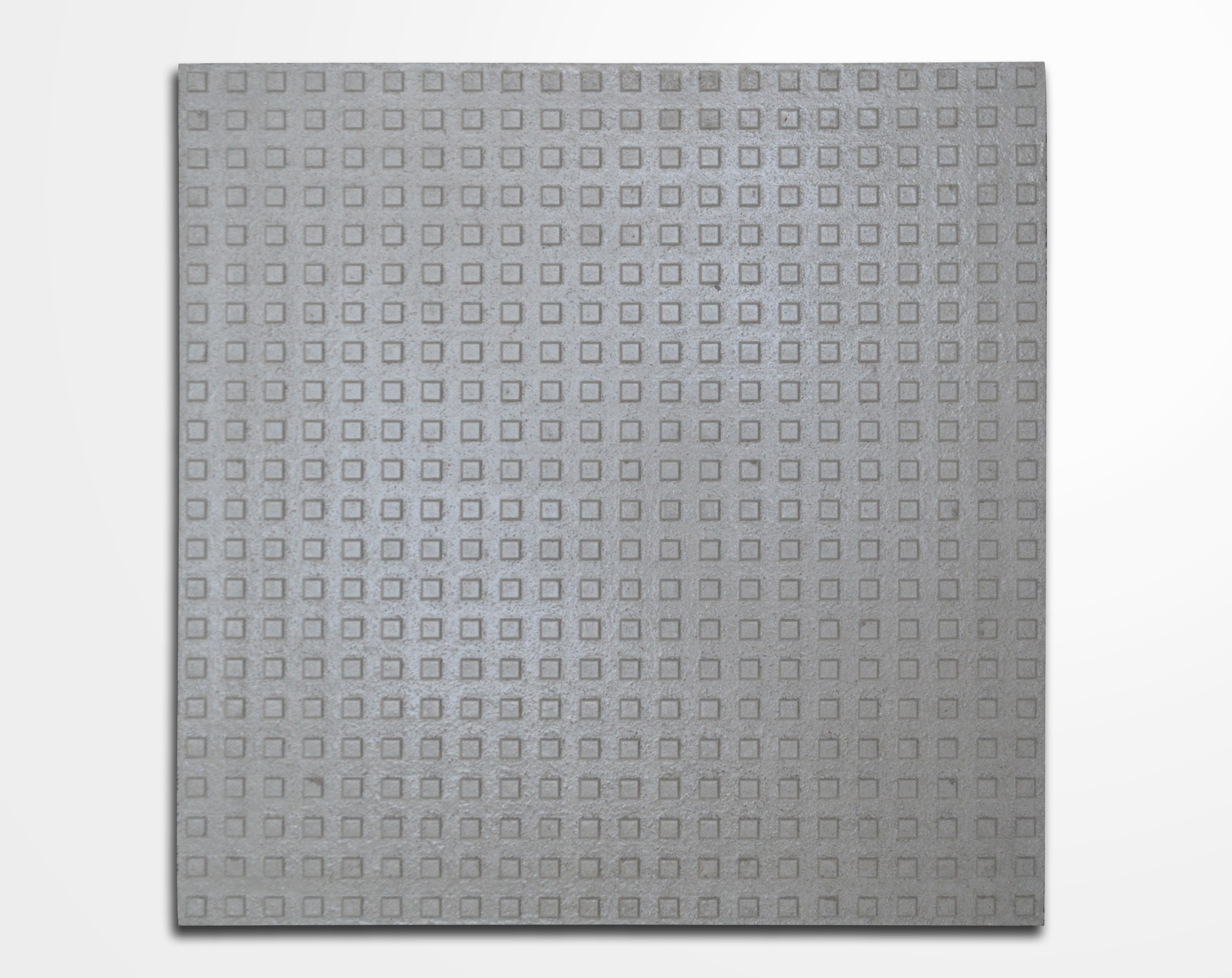

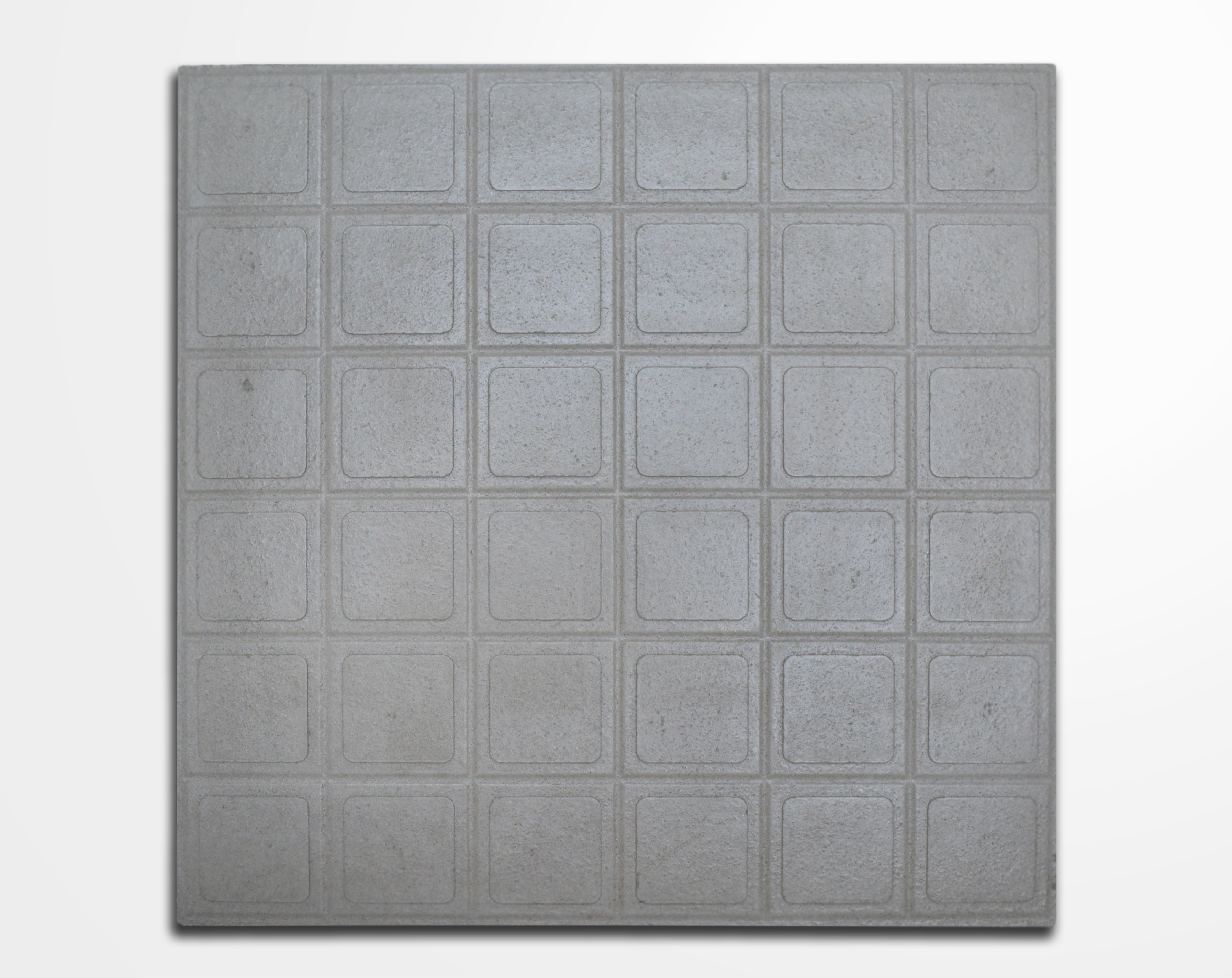

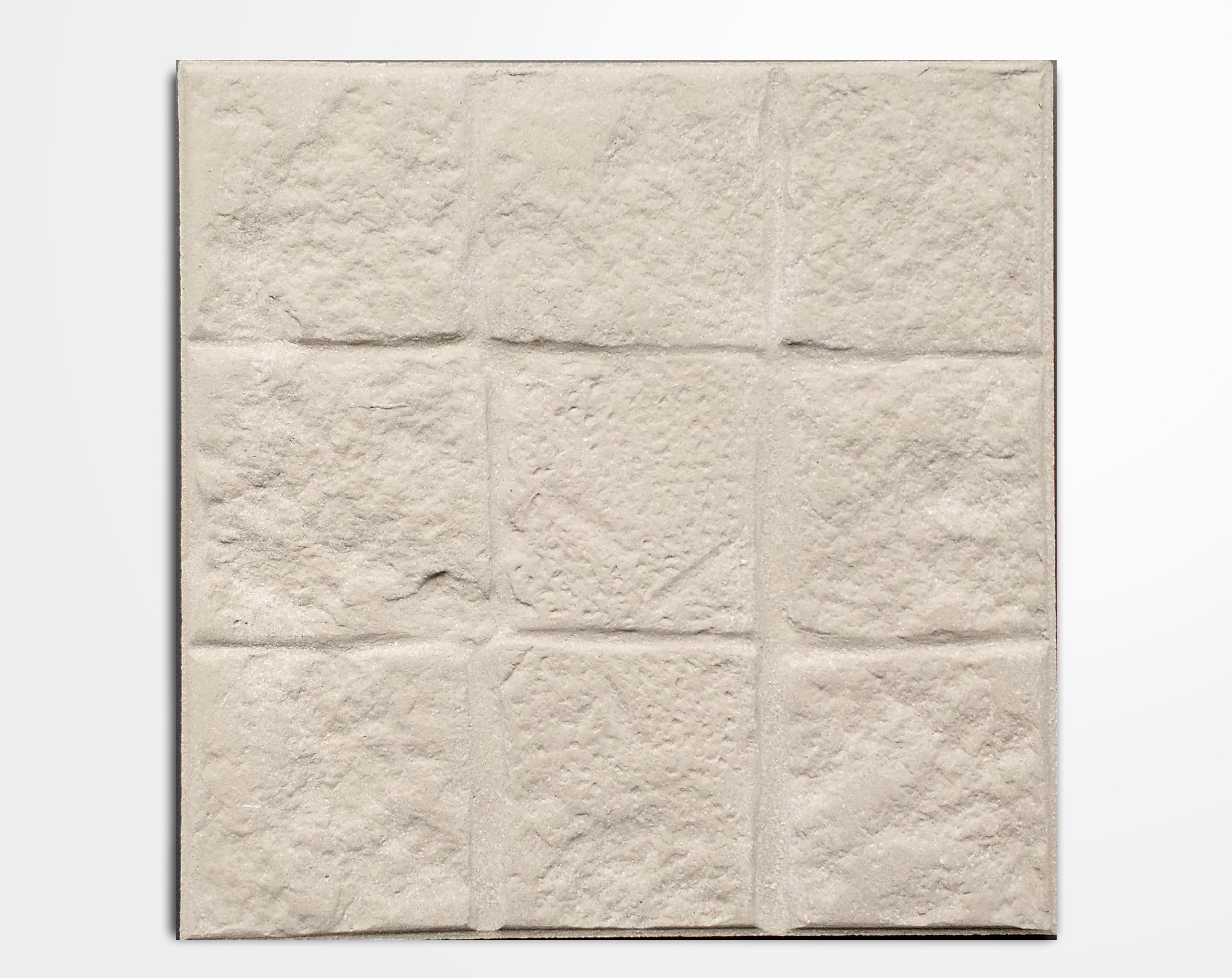

LINE OF ANTI-SLIP PRESSED SLABS

It combines strength and resistance with innovation and beauty in its different designs. The slabs have a texture that, in addition to providing an anti-slip grip, make an ideal surface for urban areas with heavy traffic, while adding a touch of decorative and contemporary design.

These slabs are made of environmentally friendly composite, manufactured with more than 60% recycled material, which reduces the carbon footprint significantly.

| FORMAT ≈ | Thickness ≈ | Piece per M2 ≈ | Weight per piece ≈ | Weight per M2 ≈ | Packaging | PCS X box | M2 X box ≈ | KG. X box ≈ |

|---|---|---|---|---|---|---|---|---|

| 300X300 mm | 13 mm | 11.1 | 2.9 KG | 32.19 KG | EN CAJA | 6 | 0.54 M2 | 17.4 KG |

INSTALLATION OF PORTLANICO®

Installation of PORTLANICO® over concrete base with Flexible Glue

THIN COMPACT ARGENTINA recommends the installation of its floors with THIN COMPACT® FLEXIBLE GLUE

- Spread a layer of FLEXIBLE glue with a 12 mm notched trowel for 300×300 mm formats, in order to maximize the properties of the slab.

- Lay the slabs with grout joints of at least 1.5 mm.

- Apply gentle even pressure on the slab to achieve maximum contact with the glue.

- It is recommended not to allow traffic to pass over the slab before 24 or 48 hours after its installation. Since our products are made with all-natural raw materials, there may be variations in the shades of the slabs displayed in our points of sale and those that are eventually delivered.

Installation of PORTLANICO® over traditional subflooring with Traditional mix

- Use a mixture of 1:1:5 (Cement-Lime-Sand) and one part, in 20 l. of water, of a plastic binder in the preparation; this provides an adequate plastic consistency improving the mortar and ensures a better adhesion.

- Paint, with a diluted pure cement slurry, the back of the slab and the subfloor without letting it dry. That is, the slab and the subfloor, one by one.

- Spread the mixture with a mason's spoon to a thickness of no more than 2 cm.

- Lay the slabs with grout joints of at least 1.5 mm.

- Apply gentle even pressure on the slab to achieve maximum contact with the mixture.

- It is recommended not to allow traffic to pass over the slab before 24 or 48 hours after its installation.

Grouting joints in both installation methods

Grouting joints is very important as it complements the filling of the gaps that the glue or mortar did not cover.

- To grout joints, verify that the grooves are clean and that 24 hours have elapsed after their installation.

- Mix two parts of grout and one part of water to obtain a light paste suitable to be inserted in the joints.

- Distribute the preparation using a container with a suitable spout so that the grout does not stain the tiles and penetrates into all the grooves.

- Grouting joints for this type of slabs requires special care since the surface with grooves and patterns has greater absorption and if not cleaned immediately, unwanted stains may remain.

- As the grout thickens, more water should be added to thin it again. If this is not done, the grout will not penetrate the joint and will only cover the top part, leaving air voids. This will cause the slabs to pop out.

- Once the joint has been properly filled, proceed to clean all the excess from both the joints and the slabs.

- It is recommended to wet the material applied in the joints with a sponge every 3 or 4 hours to avoid cracking.

Curing of PORTLANICO® slabs

The curing of the slabs is essential after installation to seal the slabs permeability. This will prevent dirt from penetrating and facilitate subsequent cleaning.

- To cure the slabs, previously wash the surface to be treated with water and, if necessary, use THIN COMPACT® cleaner, which helps to remove the remains of dirt and dust. Then rinse with plenty of water and let it dry.

- Once clean and dry, at temperatures no higher than 28 °C, apply a coat of THIN COMPACT® onSurface Coating with a spray gun, brush or roller in one direction only and allow to dry. Repeat the process to achieve a better finish.