LINE OF STONE AND WOOD-LIKE CLADDING FOR INTERIOR AND EXTERIOR USE

Its designs emulate natural stone, turning it into a highly aesthetic product. It is used to cover both interior and exterior walls.

| Products | Dimensions ≈ | Thickness ≈ | Weight ≈ per piece | Pieces per m2 | Weight ≈ per m2 | Colors |

|---|---|---|---|---|---|---|

| MENDOZA | 170 x 350 mm | 20/30 mm | 3.5Kg | 17 | 60 Kg | SIENNA/ORANGE |

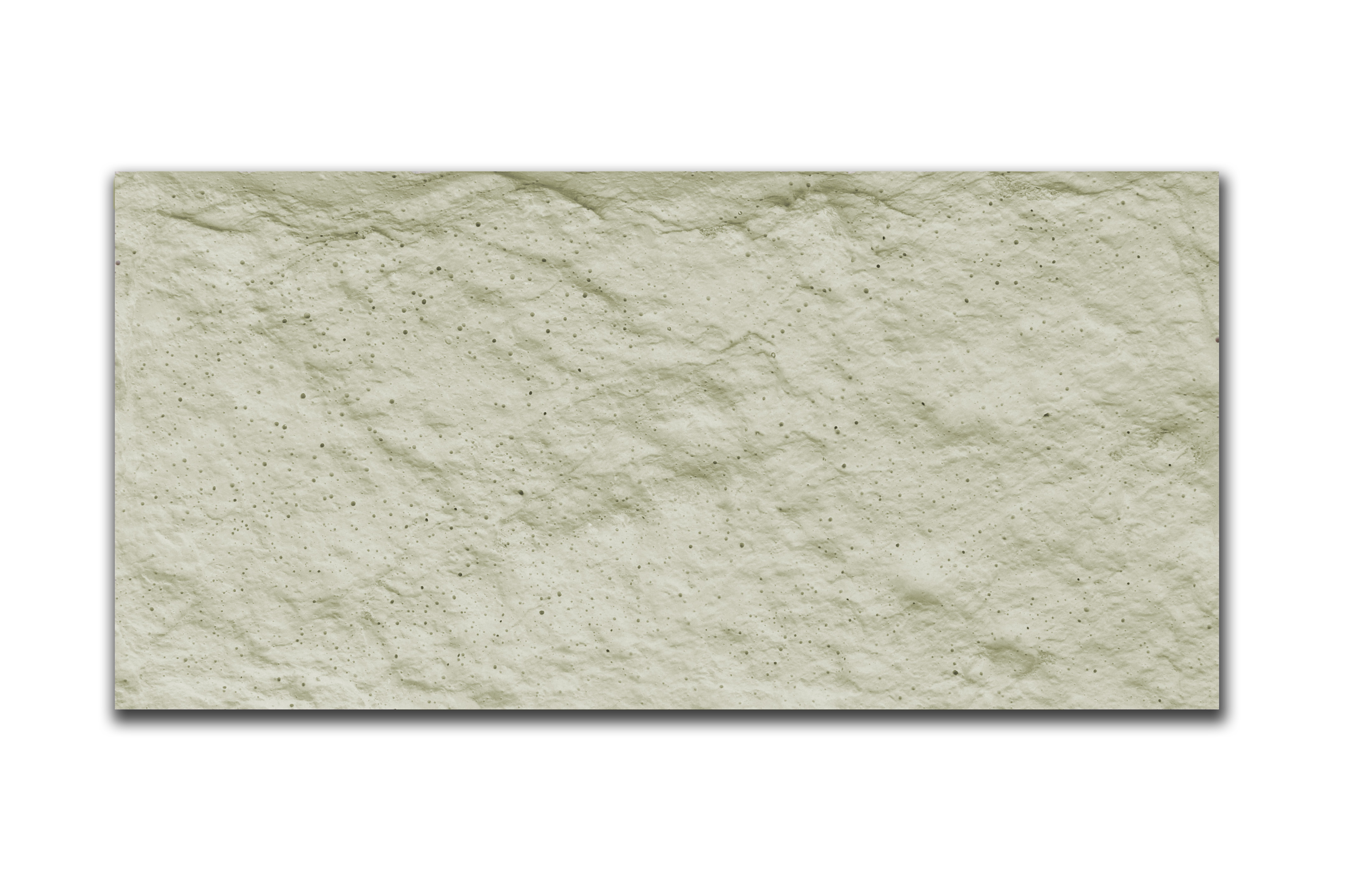

| SAN LUIS | 170 x 335 mm | 20/30 mm | 3.2 Kg | 17.5 | 56 Kg | SAN LUIS GREEN |

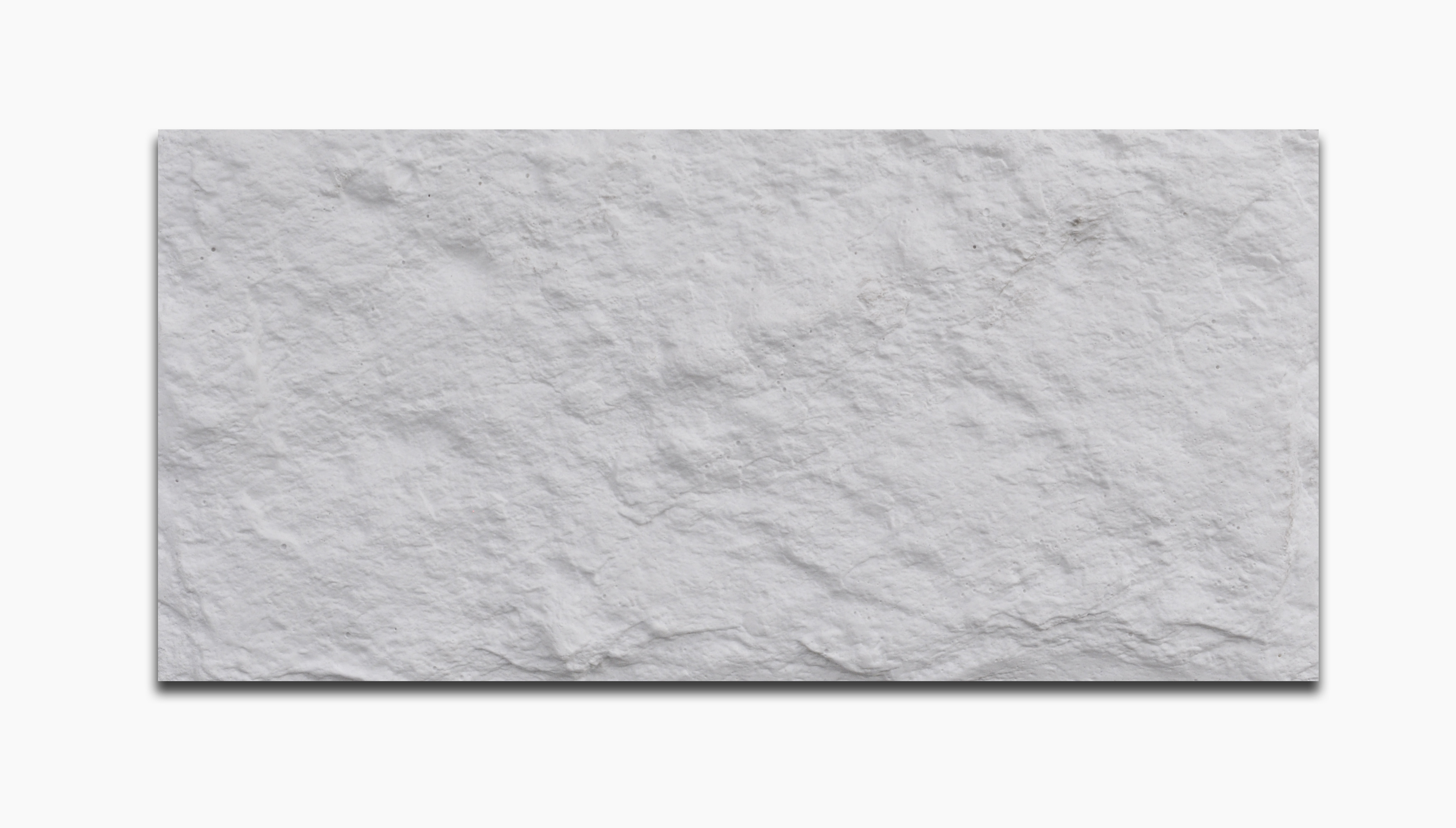

| ROCA | 190 x 390 mm | 20 mm | 3.9 Kg | 13.5 | 53 Kg | WHITE SIENNA |

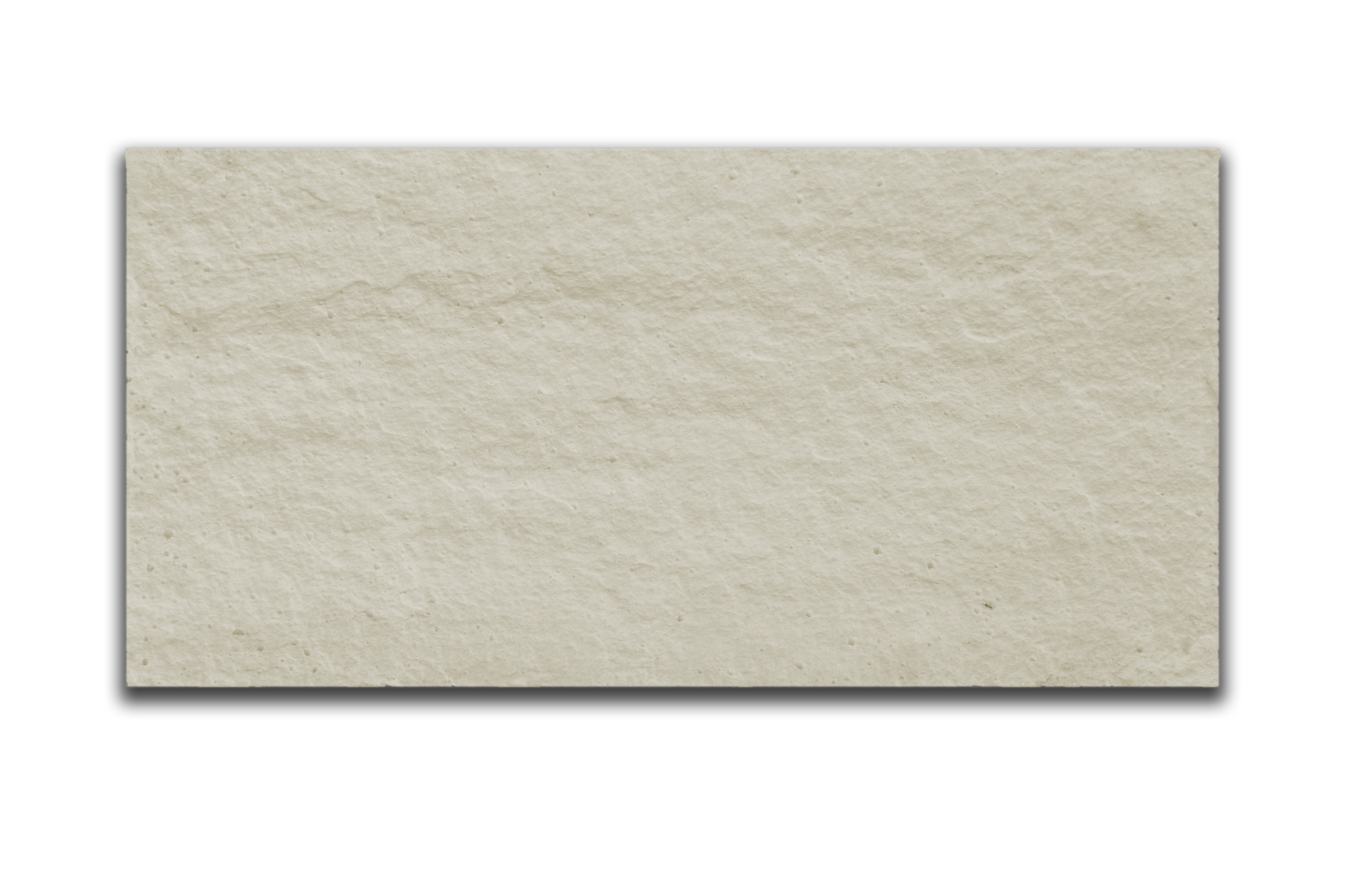

| MAR DEL PLATA | 190 x 390 mm | 20 mm | 3.9 Kg | 13.5 | 53 Kg | WHITE/SIENNA |

| PAMPA | 140 x 360 mm | 20/30 mm | 3.2 Kg | 19.8 | 64 Kg | BONE |

| WOOD-LIKE DECK | 1000 x 130 mm | 40 mm | 10.6 Kg | 7.5 | 80 Kg | WALNUT TREEL |

INSTALLATION OF THIN COMPACT® COATING STONE

Installation of THIN COMPACT® COATING STONE with Flexible Glue

THIN COMPACT ARGENTINA recommends the installation of its floors with THIN COMPACT® FLEXIBLE GLUE

- Spread horizontally a layer of FLEXIBLE glue on the slab and the surface to be coated, with a 12 mm notched trowel, in order to maximize the properties of the slab.

- Lay the slabs with grout joints of at least 1.5 mm to avoid detachment due to dilatation.

- Apply gentle, even pressure on the slab to achieve maximum contact with the glue.

- For outdoor use or in areas exposed to water, the walls must be previously waterproofed.

Grouting joints

Grouting joints is very important as it complements the filling of the gaps that the glue or mortar did not cover. In addition, it prevents water from penetrating between the plate and the wall.

- Grouting joints for these slabs can be done with CEMENTITIOUS GROUT (in a grout bag) or with CRACK SEALANT (in a tube container).

- Verify that the grooves are clean, dry and that 24 hours have elapsed after application.

- If you use CEMENTITIOUS GROUT, mix it with water until you obtain a homogeneous and viscous paste suitable for sealing grout joints.s

- Distribute the preparation using a container with a suitable spout or a grout bag so as not to stain the visible face of the slabs and to penetrate into all the grooves.

- Grouting joints for this type of slabs requires special care since the surface with grooves and patterns has greater absorption and if not cleaned immediately, unwanted stains may remain.

- Once the joint has been properly filled, proceed to clean all the excess from both the joints and the slabs.

Curing of COATING STONE slabs

The curing of the slabs is essential after installation to seal the slabs permeability. This will prevent dirt from penetrating and facilitate subsequent cleaning.

- To cure the slabs, wash the surface to be treated with plenty of water beforehand, removing the remains of dirt and dust, then let it dry.

- Once clean and dry, at temperatures no higher than 28 °C, apply a coat of onSurface Coating with a spray gun, brush or roller in one direction only and allow to dry. Repeat the process to achieve a better finish.